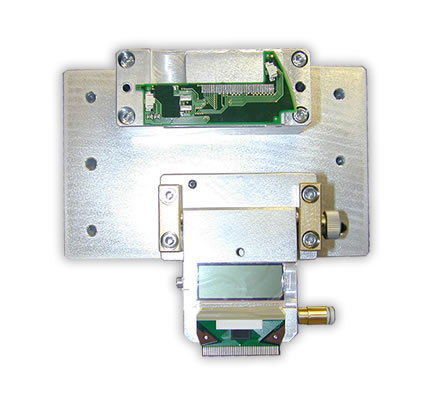

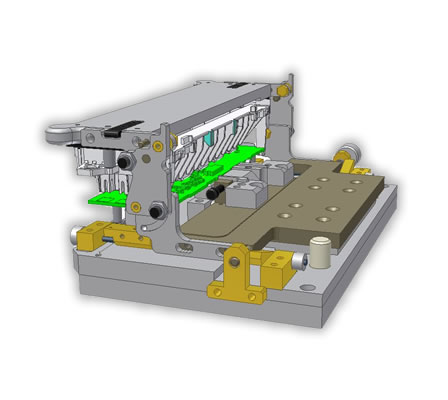

- Product jig for LCD and PCB

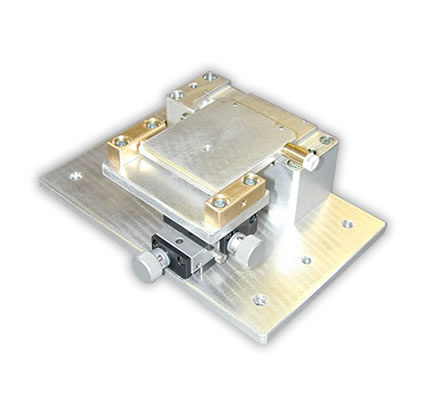

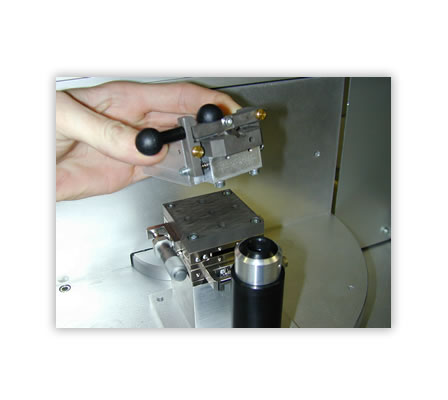

- Assembly fixture for housing

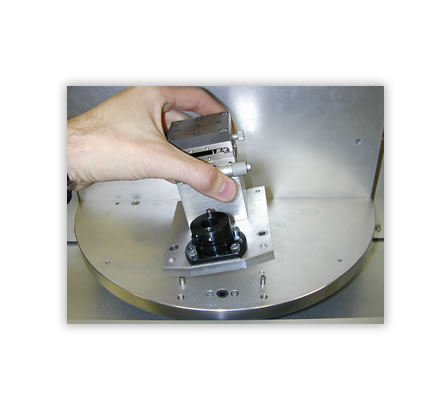

- Fine adjustment by xy-stage

- Product jig for LCD and PCB

- Assembly fixture for housing

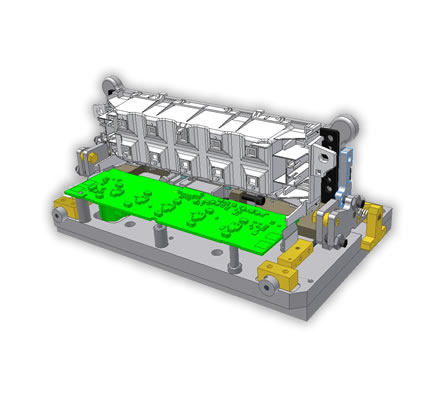

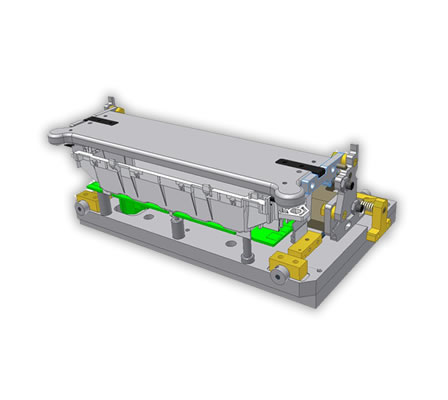

- Double product jig

- Soldering of stranded wires

- Exchangeable supports

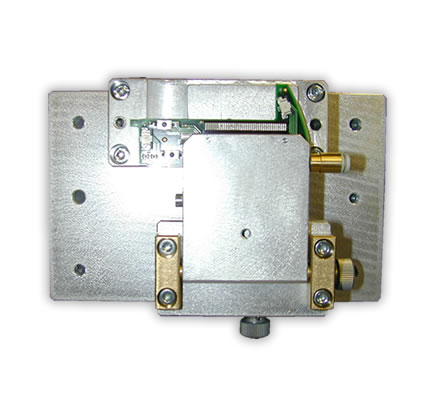

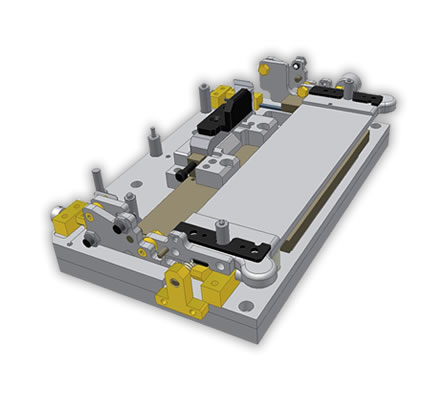

- Product jig for LCD and PCB

- Assembly fixture for housing

- Product jig for LCD and PCB

- Assembly fixture for housing

- Double product jig

- Soldering of stranded wires

- Exchangeable supports

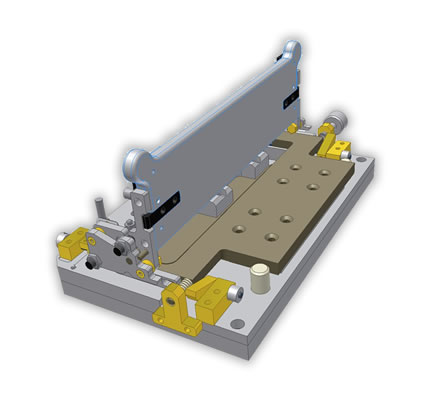

- Double product jig

- Soldering of ribbon cables

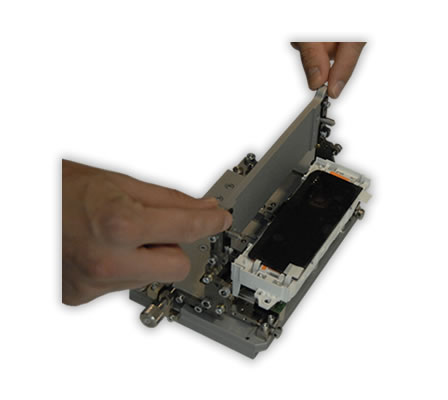

- Product jig for LCD and PCB

- Assembly fixture for housing

- Double product jig

- Soldering of single stranded wires

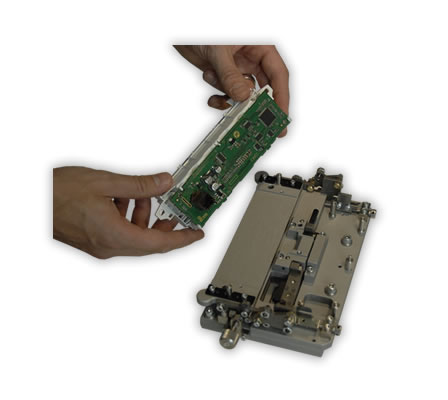

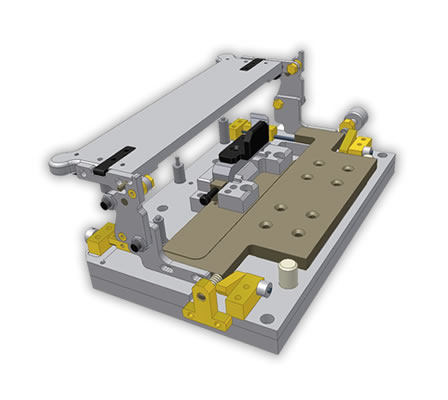

- Double product jig

- Soldering of single stranded wires

- Product jig for LCD connection flex

- Clamping device for parts

- Product jig for ribbon cables

- Cables are held by vacuum

- Product jig for ribbon cables

- Cables are held by vacuum

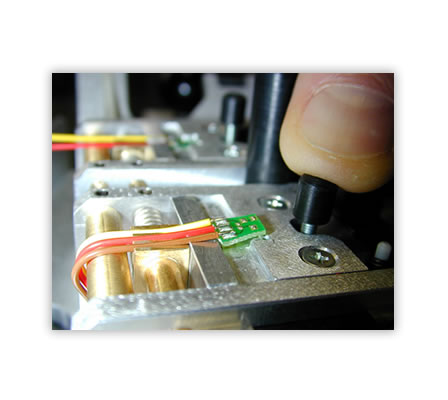

- Product jig for soldering of stranded wires

- Clamping device for wires

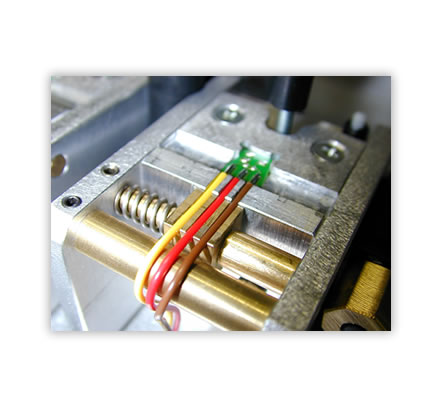

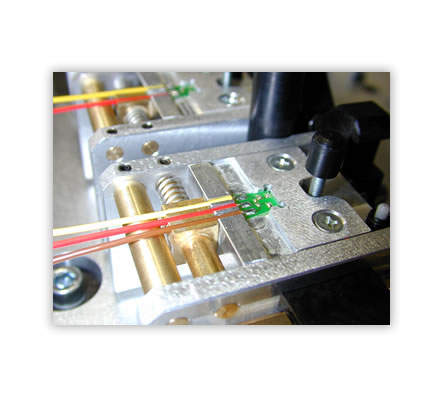

- Product jig for soldering of ribbon cables

- Fine alignment of the PCBs

- Product jig for soldering of stranded wires

- Clamping device for wires

- Product jig for soldering of ribbon cables

- Fine alignment of the PCBs