Application 2

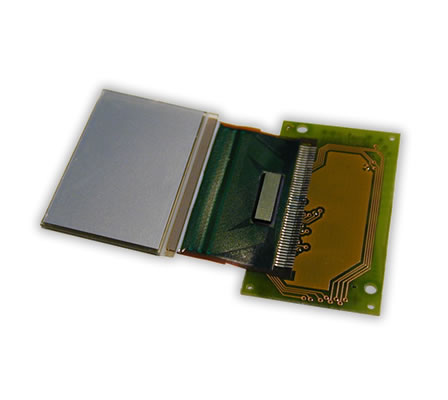

Soldering of an OLED on a PCB.

Hot Bar Soldering with flat soldering bar.

The positioning of the flex foil on the soldering pads of the PCB is realised with alignment pins and corresponding drillings in flex and PCB.

Soldering of single stranded wires on a PCB.

Use of a profiled soldering bar for the optimal positioning of the stranded wires to the soldering pads and for an improved heat input compared to a flat soldering bar.

The profiling of the soldering bar is product-specific and, therefore, can be adapted to the respective wire cross section.

There is an open choice of the number of profilings.

Profilings can be of different shapes and sizes.

Thus conductors with different cross sections can be soldered in just one process step.

Soldering of single stranded wires on a foil structure (FPC).

Use of a profiled soldering bar for the optimal positioning of the stranded wires to the soldering pads and for an improved heat input compared to a flat soldering bar.

The profiling of the soldering bar is product-specific and, therefore, can be adapted to the respective wire cross section. There is an open choice of the number of profilings.

Profilings can be of different shapes and sizes. Thus conductors with different cross sections can be soldered in just one process step.