HVS40i Inlinesystem 2

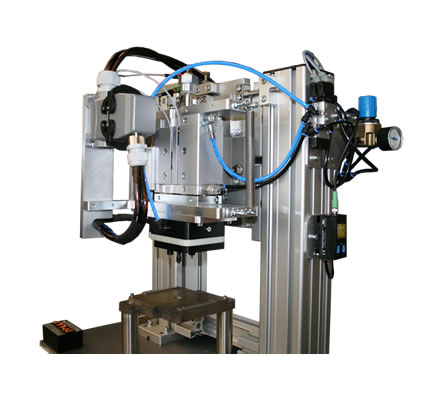

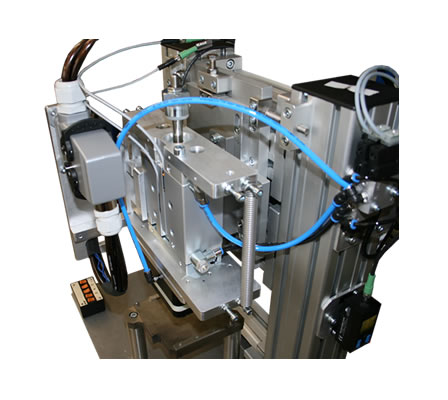

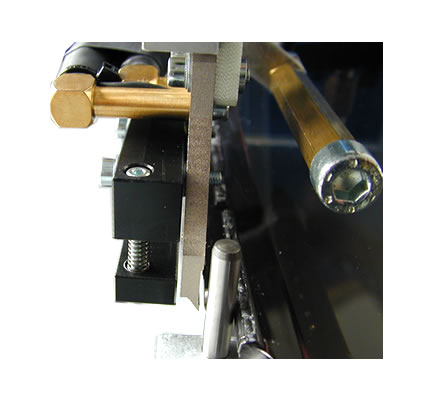

A heat staking system for integration in a customer in-line system (E.G. the Bosch TS) with workpiece carriers. In this example, the heat staking process was split into two work stations with a total of 6 positions. At each station, 3 plastic pins were formed into dome shapes. Multiple heat staking heads can be used.

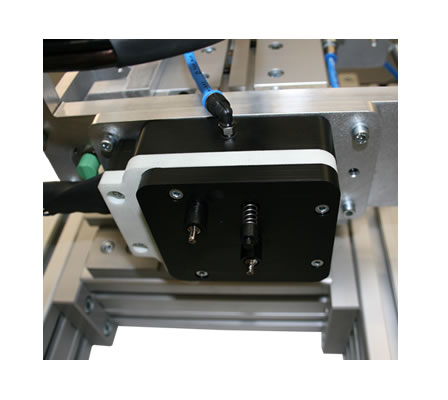

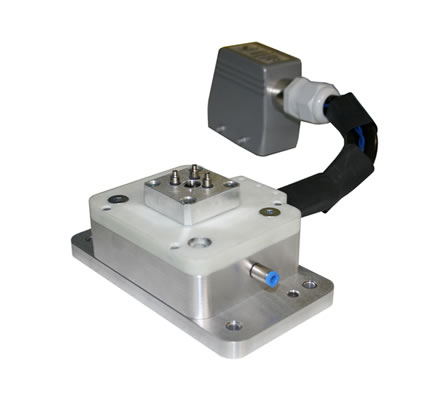

The control of the belt section of the in-line system can be taken over by the heat staking system or by the customerâs control system. The circulating workpiece holders are indexed into the working stations or raised. The indexing units are specifically designed for the fairly high forces encountered in the heat staking process. The integration of the heat staking control into the customer system takes place by means of standard interfaces (digital input/output, Profibus or TCP/IP network). The functionality of the heat staking system can therefore be monitored and controlled or process data can be transferred (Traceability)

Temporarily heated system, where active cooling of the product takes place after the heating phase.

Custom-built systems and special machines are designed, manufactured, tested and commissioned for operation in our factory. We carry out all the manufacturing stages required for the heat staking process.

We can meet customer functional specifications from simple systems, which are purely thermally monitored, to completely process-monitored expansion sections with component raised- and lowered-distance measurement, permanent force measurement and data communication.

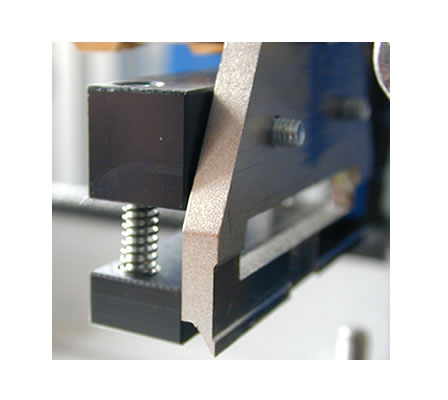

The relevant heat staking tools are matched to the product and the control circuit of the system is designed for the connection of single dies to the use of complex, multiple heat staking heads (e.g. for use in staking of 10 or more simultaneous processes. The shaping dies are manufactured in-house to meet customer specifications. The heat staking heads can be very rapidly changed over.

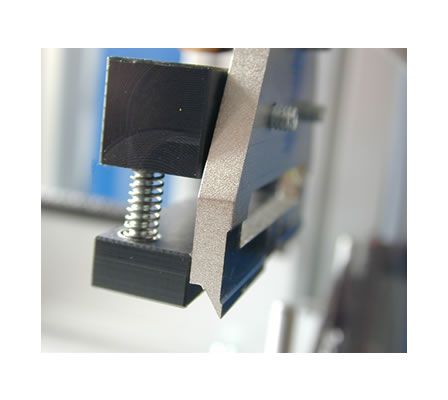

Our innovative coating technologies ensure the maximum possible operating life of the heat staking die even with extremely compact plastics and provide maximum resistance to the abrasive wear and erosion to which the forming surfaces in contact with the product are exposed. Coatings with a micro hardness (HV 0.05) up to 3,300 are used.

System control allows freely programmable heating and cooling phases, comprehensive monitoring functions (warning- and malfunction messages for all possible parameters), workpiece or maintenance counters, storage of manufacturing parameters for 10 or more products, possibility of displaying all identified process parameters etc. All changes to process-relevant parameters are password protected. Serious fault reports, (such as the breaching of malfunction values or repeated alarms) can only be overridden by means of an additional key switch.