- Inline-System

- Flux-Station

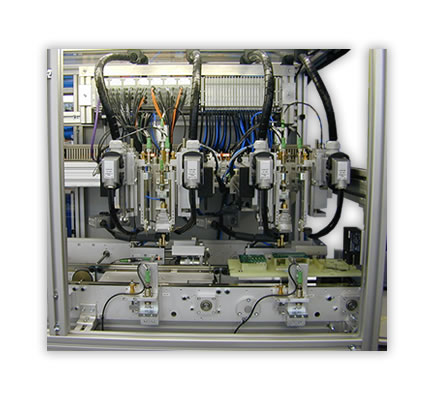

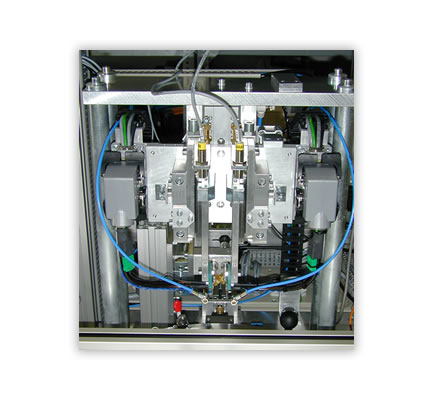

- 2 triple Hot Bar Soldering units

- Seated work position

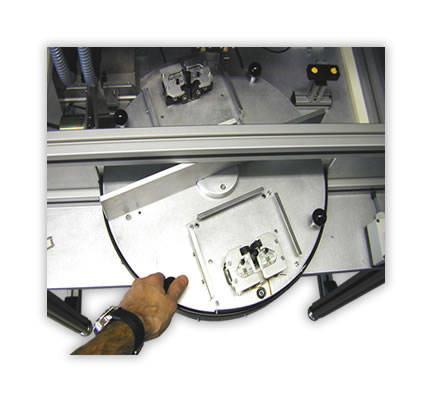

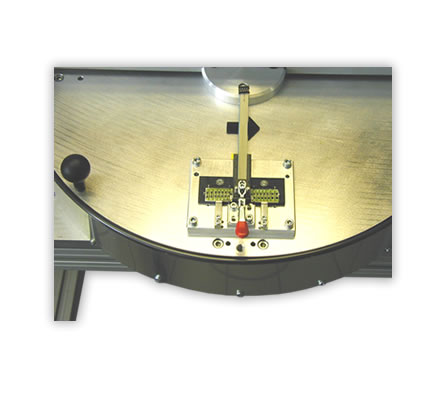

- Manual rotary table

- Customized solution

- Seated work position

- Manual rotary table

- Customized solution

- Seated work position

- Manual rotary table

- Customized solution

- Seated work position

- Manual rotary table

- Customized solution

- Seated work position

- Automatic rotary table

- With automatic flux application

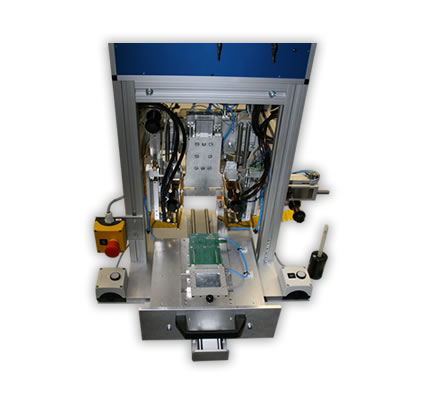

- Inline-System

- With flux station

- Two Hot Bar Soldering stations

- Six fold rotary table system

- Seated work position

- incl. AOI, Flux application etc.

- Seated work position

- Manual rotary table

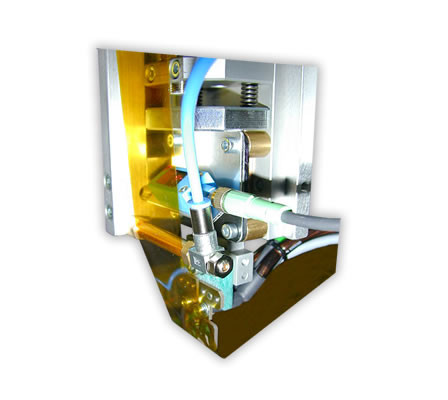

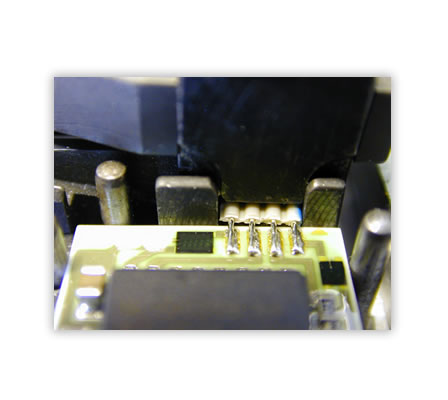

- Exchangeable Soldering heads

- Hot Bar Soldering heads

- single or double

- With Kapton foil feeder

- XYZ-Hot Bar Soldering System

- Manual movement of axes

- Separate control

- Sliding table system

- JIG with vacuum connection

- Monitor system

- Manual rotary table

- Monitor system

- Basic control

- Sliding table system

- Manual flux application

- Monitor system

- Manual rotary table

- Standing work position

- Basic control

- Inline-System

- Flux-Station

- 2 triple Hot Bar Soldering units

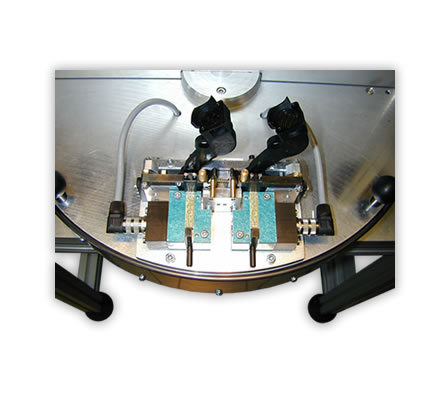

- Sliding table system

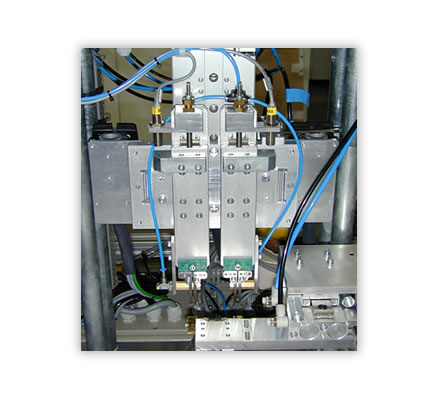

- Soldering head from left and from right side

- Automatic Kapton foil feeder

- Sliding table system

- Automatic flux application

- Seated work position

- Sliding table system

- Automatic Kapton foil feeder

- Flux pen holder

- Sliding table system

- Manual flux application

- Basic edition

- Quadruple rotary table system

- Seated work position

- Incl. AOI, Flux application, etc.

- Double Flux- and Hot Bar Soldering System

- System for integration to rotary index table device

- With Kapton foil feeder

- Sliding table system

- Automatic flux application

- Seated work position

- Manual rotary table

- Monitor system

- Single Hot Bar Soldering System

- System for integration to rotary index table device

- Standard system with sliding table

- Automatic Kapton foil feeder

- Manual flux application with flux pen

- Quadruple-Flux and Hot Bar Soldering System

- System for integration to rotary index table device

- Standard system with sliding table

- Manual flux application

- In-line system

- Flux-station

- 2 triple soldering units