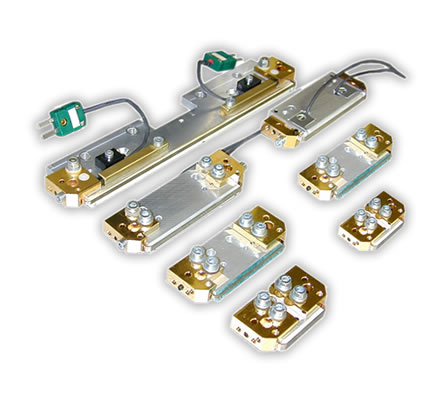

Heating rails 1

Heating rails for heat sealing systems are supplied in infinitely variable lengths from 5mm to 300mm.

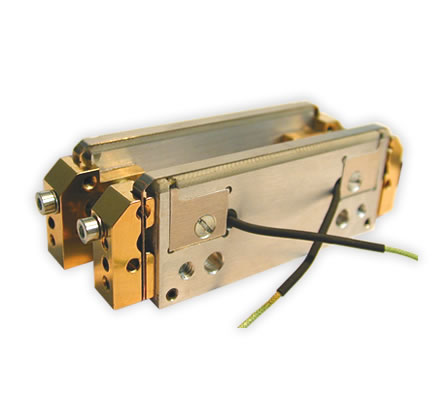

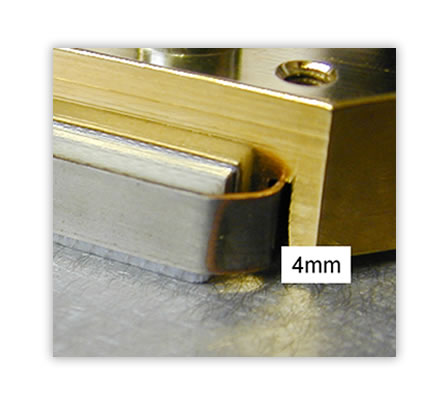

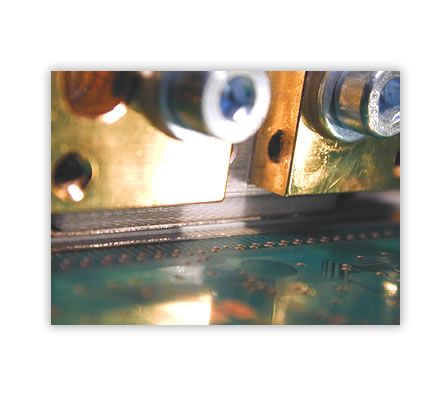

Contact units, which are gold-plated on the edges are fitted to an aluminium base and these provide electrical contacts for the measurement wires of the control electronics and the heater connection wires.

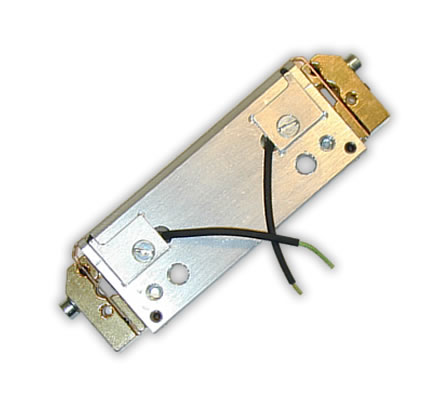

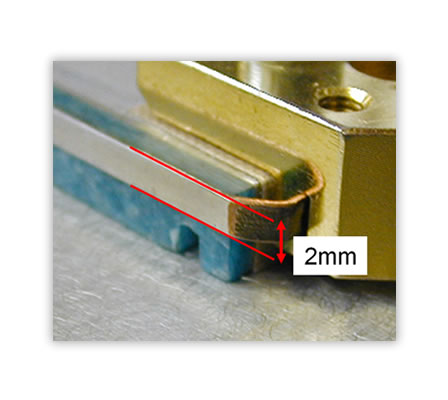

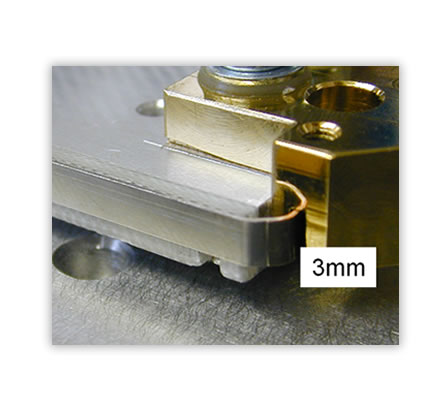

The actual heater elements, the so-called heater strips, are thermally insulated from the base and fixed to the contact units by a âbelt tensioning systemâ.

The heater strips have a low thermal mass, so that they are heated and cooled in the shortest possible time.

At several points on the inside of the heating strips there are additional temperature sensors for collective temperature monitoring.

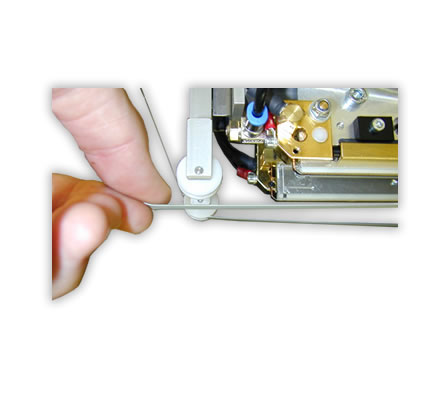

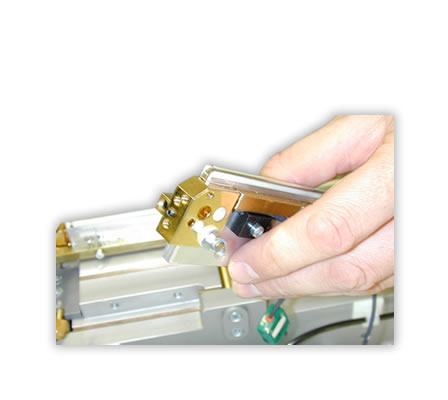

The heater rails are extremely robust and durable. Replacement, e.g. at product change-over, is achieved with few handgrips.

In complex production plants, the heater heads are fitted on semi-gimballed mountings on replaceable units.