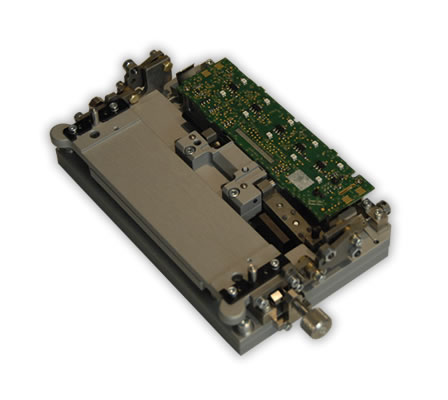

- Product jig for LCD and PCB

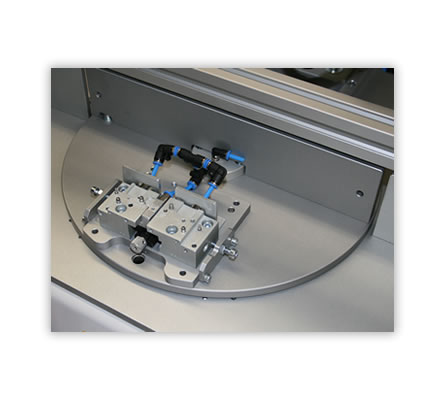

- Assembly fixture for housing

- Fine adjustment by xy-stage

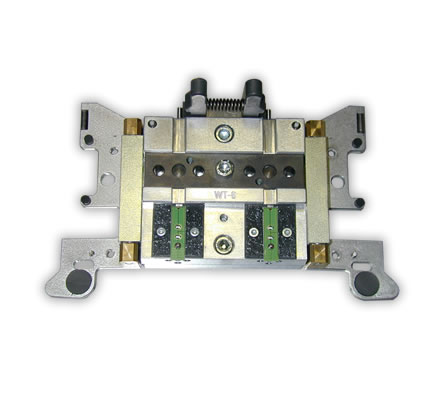

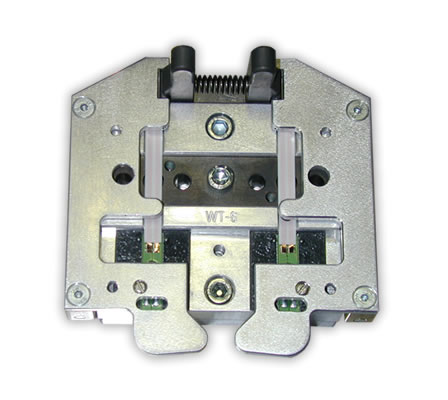

- Product jig for LCD and PCB

- Assembly fixture for housing

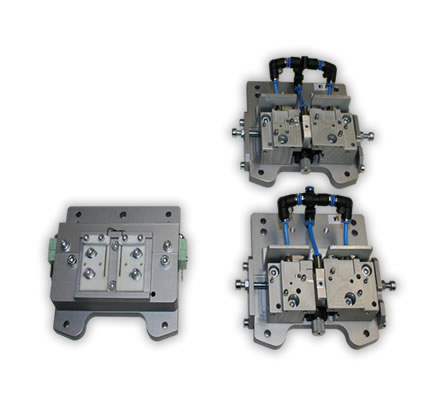

- Double product jig

- Soldering of stranded wires

- Exchangeable supports

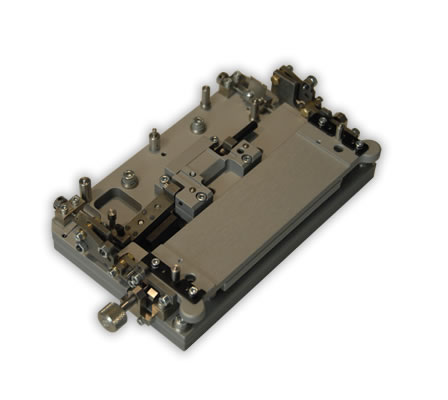

- Product jig for LCD and PCB

- Assembly fixture for housing

- Product jig for LCD and PCB

- Assembly fixture for housing

- Double product jig

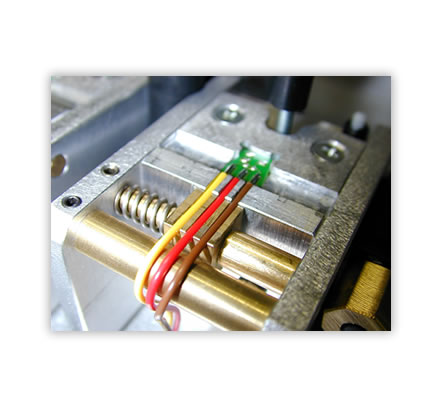

- Soldering of stranded wires

- Exchangeable supports

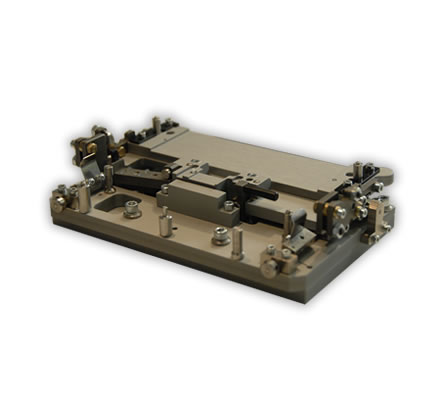

- Double product jig

- Soldering of ribbon cables

- Product jig for LCD and PCB

- Assembly fixture for housing

- Double product jig

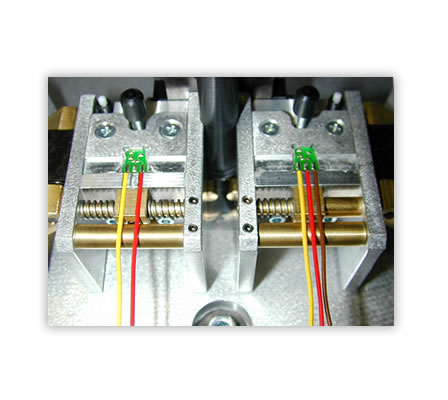

- Soldering of single stranded wires

- Double product jig

- Soldering of single stranded wires

- Product jig for LCD connection flex

- Clamping device for parts

- Product jig for ribbon cables

- Cables are held by vacuum

- Product jig for ribbon cables

- Cables are held by vacuum

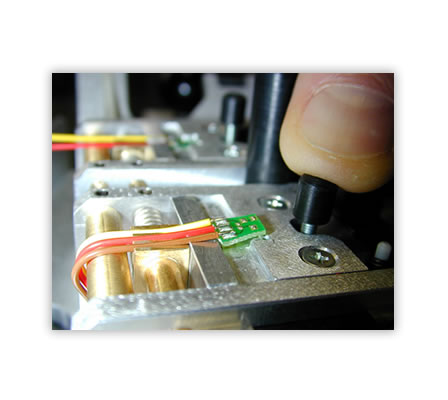

- Product jig for soldering of stranded wires

- Clamping device for wires

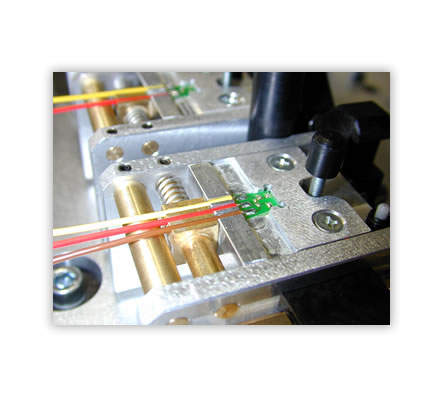

- Product jig for soldering of ribbon cables

- Fine alignment of the PCBs

- Product jig for soldering of stranded wires

- Clamping device for wires

- Product jig for soldering of ribbon cables

- Fine alignment of the PCBs